BLACKS

CNM - Charpy/Izod

BLACKS

CNM - Charpy/Izod

Specimen Preparation Machines

The Blacks CNM range of machines have been specially designed to allow laboratories and test houses to produce their own standard and sub-size Charpy / Izod test pieces ready for cutting the appropriate notch.

Two variations of the Charpy Specimen Milling Machine (CNM) are available to cover a wide range of materials.

CNM-158A1 FIXED SPEED

CHARPY SPECIMEN MILLING MACHINE

The Fixed Speed Machine is recommended for customers who are producing

specimens in carbon steels, easily machined low alloy steels, non-ferrous

and plastic materials.

This machine has a fixed cutter speed of

1.98 m/sec(50Hz), 2.38m/sec(60Hz) and a variable feed rate for the samples

of 2.5-9.0 mm/sec.

For customers producing specimens in a wider range of materials, see

the

CNM 140A1 with variable cutter speed.

CNM-140A1: VARIABLE SPEED

CHARPY SPECIMEN MILLING MACHINE

The Variable Speed Machine is recommended for customers

who are producing specimens in carbon steels, more difficult to machine

alloy steels, stainless steels, non-ferrous and plastic materials.

Please contact RJW Ltd if cutting superalloys.

This machine has a variable cutter speed of

1.0-2.5 m/sec and a variable feed rate for the samples of 2.2-9.0 mm/sec.

The varying of the cutter speed for differing materials improves the

cutter tip life.

Machine Design and Method of Operation

Machine Design:

The machines are of robust design and construction, enabling them to

produce

specimens to the surface finish and tolerances required by International

Standards.

Both machines are designed for mounting onto a customer’s bench and are

fitted

with an easily removable swarf (cuttings) tray.

The cutting process is carried out without cutting fluids.

A fully encapsulating removable cover allows ready access to the motor and

drive

for periodic maintenance.

A D.C. thyristor drive control provides the variation in speed

of the rotary fixture, for both the Fixed and Variable Machines.

The fixture speed sets the feed rate which the samples are machined.

An A.C. thyristor drive control provides the variation in the

cutter speed, on the Variable Machine only.

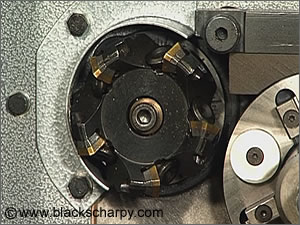

Work Holding Fixture:

The circular fixture allows up to four specimens to be machined during the

same operation.

Various clamps, anvils and clamping screws are available to suit the type

of rough cut blanks being used.

One circular fixture is included with each machine. For maximum machine

production a 2nd fixture (optional extra) is recommended, so that whilst

the 1st fixture is being machined, the 2nd fixture can have its samples

loaded.

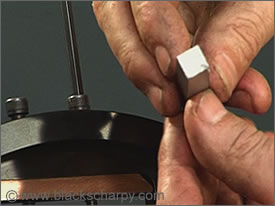

Cutter:

The cutter is fitted with five ISO carbide inserts, which are easily

replaceable.

A micro adjuster allows for accurate control of specimen size and allows

for compensation of cutter tip wear.

MACHINE SPECIFICATION

Overall Size:

Fixed Speed Machine

900 x 500 x 650 mm

Variable Speed Machine

900 x 500 x 715 mm

Weight: 210 Kg

Electrical Supply:

380 or 415 or 440 Vac

(customer to advise their voltage for setting at

our works)

3 phase, 50/60 Hz, 4 KVA

480 Vac optional

DEMONSTRATION VIDEO

View a 10 minute video

showing the operation of our Charpy and Izod Specimen Machine.

PRODUCTION RATE

Fixed Speed Machine

Using two work holding fixtures, 4

machined specimens can be produced every 20 minutes with the feed rate set

in a mid-position . The mid position is a typical setting for general

carbon steels.

Variable Speed Machine

No

specific production rate can be quoted for the variable speed machine due

to the variation in machine feed & speed settings, which are dependent

upon the sample material.

ACCESSORIES

![]() Additional

rotating fixtures complete with clamps, anvils, clamping screws and a

bench mounted holding bracket. The customer to advise pocket

configuration.

Additional

rotating fixtures complete with clamps, anvils, clamping screws and a

bench mounted holding bracket. The customer to advise pocket

configuration.

![]() Sub-size

specimen fixtures and a bench mounted holding bracket. The customer to

advise the sub-sizes required, for the fixture to be set at our works.

Sub-size

specimen fixtures and a bench mounted holding bracket. The customer to

advise the sub-sizes required, for the fixture to be set at our works.

![]() ISO

replaceable inserts.

ISO

replaceable inserts.

![]() Specimen size

go/no go gauges

Specimen size

go/no go gauges

![]() supplied

with UKAS certificate.

supplied

with UKAS certificate.

SPARES

Spare parts and consumables for all machines available: Spare Parts

SPECIMEN MATERIALS

By arrangement, special

testing may be undertaken using our in-house test facility to determine

optimum equipment for difficult to machine materials.

Contact us, stating the

specimen’s material, size & standard, for further guidance.

CNM user manual available to download.

DOWNLOADS page.

Motorised Broaching Machines

An ideal accompaniment to the specimen machines are our Motorised Charpy

Broaching Machines.

QUALITY

Each machine undergoes a full inspection, run-in period and test

cycle prior to despatch.

CE marking

Approved by

independent company.

CE TECHNICAL DOCUMENTS

Held at RJW Ltd, Unit A5 Chaucer Business Park, Kemsing, Kent.

WEEE

Environmental registration:

WEE/DC 2117VU

PRODUCER COMPLIANCE SCHEME

With Clarity Environmental Ltd.

Method of Operation:

The rotating work holding fixture is fitted with clamps, anvils and

clamping screws to suit the type of blank being used, i.e. rough sawn

square/rectangular, round or tubular section and the size of specimen to

be produced, i.e. 10mm square or sub-size.

For ease of fitting samples, the fixture is removed from the machine and placed onto a bench mounted holding bracket, one bracket is supplied with each fixture.

Up to four rough cut samples may be loaded into the fixture, which is then re-mounted onto the machine spindle and the cutting cycle started.

The machine cuts the first side of the samples (1st cut).

The fixture is then removed from the machine, turned through 180 degree and refitted to cut the second side of the samples (2nd cut).

After completion of the 2nd cut, the fixture is removed from the machine and placed onto the bench mounted holding bracket.

The samples are removed and remounted into the fixture at 90 degrees. The fixture is then mounted into the machine to cut the third side (3rd cut). The fixture is then rotated to cut the fourth side (4th cut), which completes the production of the 10mm square samples.

Adjustment of the micro-adjuster may be necessary to achieve the required size and dimensional accuracy of the finish machined specimen.

1st & 2nd cut clamp

3rd & 4th cut clamp

10mm Square Specimens

16mm maximum square rough sawn and 18mm maximum

diameter

section blanks in carbon and low alloy steels can be used, to produce 10mm square specimens to

International Specification Standards.

The fixture pocket

configuration:

![]() A machine with

1 fixture; 2 pockets with 1st & 2nd cut clamps & 2 pockets with 3rd & 4th

cut clamps.

A machine with

1 fixture; 2 pockets with 1st & 2nd cut clamps & 2 pockets with 3rd & 4th

cut clamps.

![]() A machine with

2 fixtures; 1st fixture, 4 pockets with 1st & 2nd cut clamps. 2nd fixture, 4

pockets with 3rd & 4th cut clamps.

A machine with

2 fixtures; 1st fixture, 4 pockets with 1st & 2nd cut clamps. 2nd fixture, 4

pockets with 3rd & 4th cut clamps.

The customer to advise if round

or tube section samples are to be used in 1st & 2nd cut pockets, as “V”

serrated anvils will be required.

Customers can order fixtures, with

any pocket configuration to suit their requirements.

Sub-size

Specimens

Sub-size

Specimens

Sub-size specimens can be machined using a work

holding fixture with special factory fitted cartridges. The 10mm dimension

is produced on a standard fixture, using 1st & 2nd cut clamps. The 3rd & 4th

cuts are machined on a sub-size fixture, which is set at our factory to

produce the thinner sub-size thickness.

Standard fixture options available

OPTION 1 – Fixture for 7.5mm specimen – 3rd cut

cartridges set to 8.75mm & 4th cut set to 7.5mm

OPTION 2 –

Fixture for 6.7mm specimen – 3rd cut cartridges set to 8.0mm & 4th cut

set to 6.7mm

OPTION 3 – Fixture for 5.0mm specimen – 3rd cut cartridges set to 6.25mm

& 4th cut set to 5.0mm

OPTION 4 – Fixture for 3.3mm specimen –

3rd cut cartridges set to 4.4mm & 4th cut set to 3.4mm

OPTION 5 –

Fixture for 2.5mm specimen – 3rd cut cartridges set to 3.6mm & 4th cut,

set to 2.6mm

Please note that 4th cut pocket cartridges for the

3.3mm & 2.5mm specimens will be set to 3.4mm & 2.6mm to allow for 0.1mm

to be ground off, to achieve their final thickness tolerance.

Customers can order fixtures with any pocket configuration to suit their

requirements.

For instance a combined fixture for 7.5mm and 5mm specimens.

1 off

each cartridge set to 8.75mm, 7.5mm, 6.25mm and 5mm.

Please note

the maximum depths of cut that can be machined on each type of sub-size

fixture are:

Fixture for 7.5mm specimen – 2.0mm

Fixture for

6.7mm specimen – 2.00mm

Fixture for 5.0mm specimen – 1.75mm

Fixture for 3.3mm specimen – 1.50mm

Fixture for 2.5mm specimen –

1.00mm